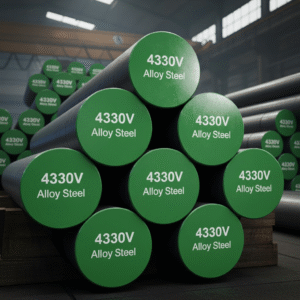

EN9 carbon steel is a medium-carbon engineering steel (≈ 0.50–0.60% C) known for its good strength, machinability, and wear resistance. EN 9 material performs reliably in shafts, axles, and other general engineering components where durability is important.

As trusted steel manufacturers in UAE and metal traders supplying ferrous metals across Oman and Saudi Arabia, we offer EN9 carbon steel in standard and custom sizes. You can flame or induction harden this steel to improve surface hardness while maintaining its toughness for demanding applications.

Key Advantages of EN9 Steel

- Medium-carbon steel with good strength and toughness

- Excellent machinability in normalized condition

- Can be surface-hardened via flame or induction

- Ideal for shafts, crankshafts, gears, cams, and machine components

- Supplied by reliable steel manufacturers in UAE and the Gulf region