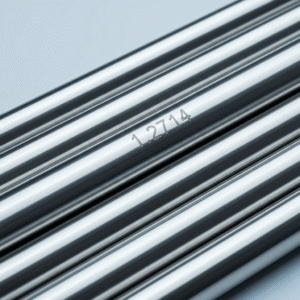

Technical Specifications

Chemical Composition

- Carbon (C): 0.35–0.45% – Provides base steel strength and good hardenability.

- Silicon (Si): 0.20–0.40% – Supports deoxidation and strength.

- Manganese (Mn): 1.30–1.60% – Improves toughness and ductility for mould applications.

- Chromium (Cr): 1.80–2.10% – Enhances hardenability and wear resistance.

- Molybdenum (Mo): 0.15–0.25% – Boosts elevated temperature strength and hardenability.

- Phosphorus (P): ≤ 0.035% – Maintains toughness and prevents brittleness.

- Sulfur (S): ≤ 0.035% – Ensures machinability and finish quality.

Treatment

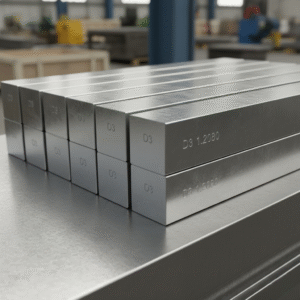

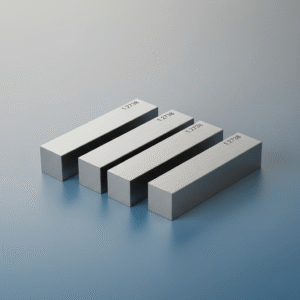

- Pre-Hardened Condition: Supplied with pre-hardened hardness around 28-32 HRC, eliminating the need for large additional heat-treatment steps and reducing risk of distortion.

- Annealing / Stress Relief: If machining is required, heat to approx. 760-790 °C then furnace-cool slowly to reduce residual stresses and achieve machinable condition.

- Nitriding / Surface Hardening: Suitable for nitriding to enhance surface hardness and wear life while retaining core toughness and dimensional stability.

- Polishing & Machining: Excellent polishability and etch fine-grain structure make it ideal for high surface finish tooling and precision moulds.