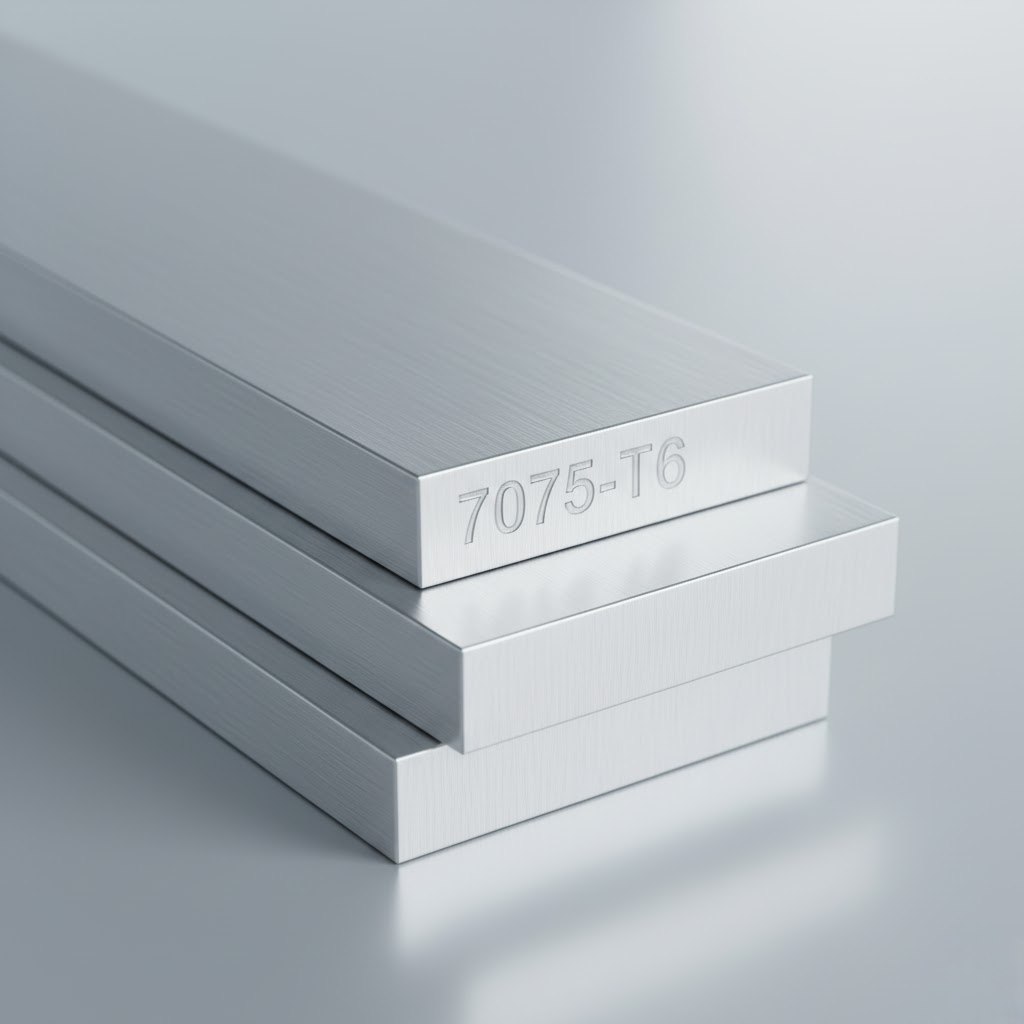

Aluminium alloy 7075 T6 delivers high strength, exceptional mechanical properties, toughness, and resistance to fatigue. 7075 T6 aluminum suits structural, precision, and high performance engineering applications. Its excellent machinability and wear resistance allow engineers to use it for aerospace, defense, automotive, and marine components.

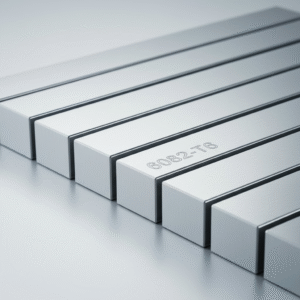

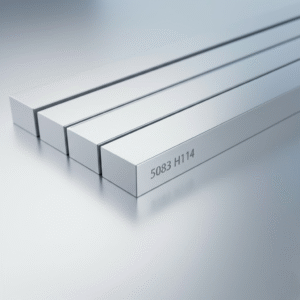

Industrial metal suppliers and aluminium manufacturers in UAE, along with metal trading companies in UAE and metal engineering Oman, provide 7075 T6 al as aluminum plate, aluminium sheets, bars, and forgings. These suppliers ensure consistent quality and reliable delivery for demanding industrial projects.

Key Benefits of Aluminium Alloy 7075 T6

- High-strength aluminium alloy with excellent fatigue and stress resistance.

- Good machinability and wear resistance for fabrication.

- Available as aluminum plate, aluminium sheets, bars, and forgings.

- Ideal for aerospace, defense, automotive, and marine applications.

- Supplied by reliable aluminium manufacturers and non ferrous metals suppliers.

- Meets international standards with optional mill test certification.