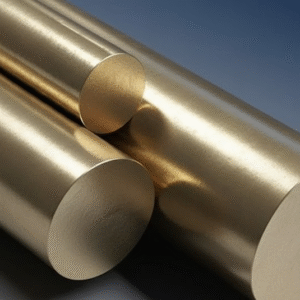

Technical Specifications

Specifications & Mechanical Properties

- Copper (Cu): ~85% – base matrix.

- Tin (Sn): ~5% – improves corrosion resistance and strength.

- Lead (Pb): ~5% – enhances machinability.

- Zinc (Zn): ~5% – contributes to strength and wear resistance.

- Density: ~8.83 g/cm³ – heavy and robust material.

- Ultimate Tensile Strength (UTS): ~270 N/mm² – high load capability.

- Proof Strength (0.2%): ~100 N/mm² – moderate strength for applications.

- Elongation: ~13% – good ductility.

- Hardness: ~75 HB – moderate hardness.

- Processing / Treatment: Supplied cast; machining enhanced by lead content.

Thermal, Electrical & Miscellaneous Properties

- Melting Point (Approx): ~1010 °C – high temperature resistance.

- Thermal Conductivity: ~71.9 W/m·K – efficient heat transfer.

- Coefficient of Thermal Expansion: ~18 ×10⁻⁶ /K (20‑200 °C) – moderate thermal growth.

- Electrical Conductivity: ~15% IACS – moderate conductivity.

- Wear & Abrasion Resistance: Good under light to moderate loads.

- Corrosion Resistance: Reasonable in sea water and brine.

- Machinability: Excellent – ideal for pump, valve, and bearing components.