Choosing the right engineering plastics over traditional metals is a strategic decision that depends on the specific demands of your industrial environment. In the competitive landscape of the GCC, where heat and corrosion are constant challenges, understanding when to switch materials can significantly improve operational efficiency and reduce long term costs.

Technical Advantages of Engineering Plastics: Weight and Corrosion Resistance

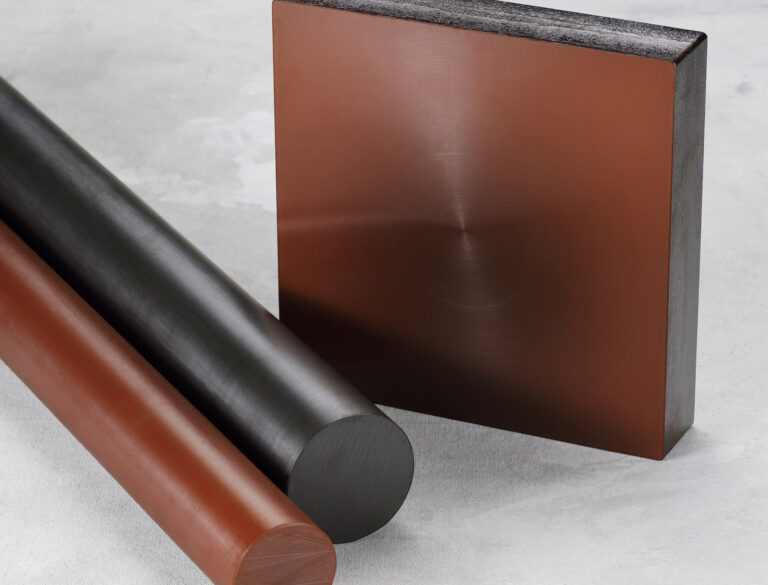

In many applications within the metal industries in UAE, weight reduction is a primary goal. Engineering plastics, such asnylon plastic, are significantly lighter thanferrous metals. This lightweight nature is ideal for moving parts, as it reduces energy consumption and wear on machinery.

Furthermore, unlike most metals, high performance polymers do not rust. This makes them the perfect choice for humid or chemically aggressive environments. Any leading plastic manufacturing company will recommend these materials for components like gears, bearings, and seals where self lubrication and chemical resistance are more important than raw structural power.

When to Choose Industrial Metals Over Engineering Polymers

Despite the rise of polymers, ferrous and non ferrous metals remain the standard for heavy duty structural applications. If your project involves extreme temperatures or requires immense load bearing capacity, a reliable industrial metal supplier will typically suggest steel or specialized alloys.

For instance, metal manufacturing companies in UAE often choose high strength steel supply for framework and large scale construction. Similarly, copper bars remain irreplaceable in electrical engineering due to their superior conductivity. When structural integrity and heat resistance are non negotiable, traditional ferrous material is still the superior choice.

Sourcing Industrial Engineering Plastics and Metals in the GCC

Finding a reliable partner is essential for maintaining project timelines. Top metal trading companies in UAE maintain a diverse inventory of both metals and plastics. This allows businesses in metal engineering Oman to source everything from structural beams to specialized industrial polymers from a single expert source.

Experienced metal traders provide technical advice on material selection, helping you understand when to transition from a metal component to a high performance plastic part. By working with a trusted metal trading company, you ensure that your materials meet international standards, whether you are dealing with plastic manufacturers or steel mills.

Decision Guide: Selecting Engineering Plastics vs Traditional Metals

Ultimately, the choice depends on your specific application. While metals have a lower initial cost in some formats, engineering plastics often reduce long term maintenance expenses. Professional plastic manufacturers offer solutions that do not require frequent lubrication, making them a cost effective choice for precision engineering.

Whether you are part of the growing infrastructure in Saudi Arabia or Oman, partnering with an experienced industrial metal supplier ensures you make the most efficient choice. Balancing the strength of metals with the versatility of plastics will drive the success of your industrial operations across the GCC region.