In the modern world, Engineering Plastics are essential for industrial success. In fact, they help businesses significantly enhance cost efficiency and performance. While traditional ferrous and non ferrous metals were the industry standard for years, the market is now changing. Consequently, engineers are choosing smarter material solutions. Therefore, a plastic manufacturing company is often the first choice for modern projects today.

Why Engineering Plastics Offer Superior Performance

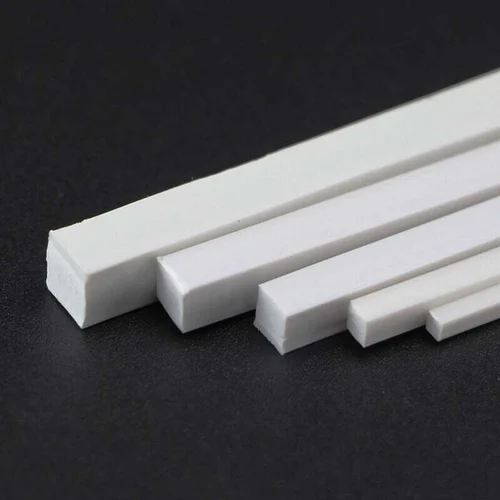

Specifically, Engineering Plastics provide a unique combination of strength and flexibility. For instance, materials like nylon plastic are incredibly durable. Moreover, they are much lighter than heavy iron bars or traditional ferrous material. As a result, this lightweight nature reduces the energy required for moving parts.

Many industries still rely on a stainless steel supplier. However, switching to high performance plastics often offers better chemical resistance. Additionally, it ensures lower friction for smoother industrial operations.

Achieving Cost Efficiency with High Performance Plastics

Maintenance costs often eat up profit margins in manufacturing. Fortunately, Engineering Plastics help solve this problem effectively. Unlike copper bars, these plastics do not rust or corrode. In addition, they are self lubricating and inherently durable.

Therefore, by using these plastics, companies can reduce the frequency of replacements. Consequently, this saves a lot of money over time. Whether you use a metal trading company or a plastic manufacturing company, the long term ROI is very clear.

Engineering Plastics in the Middle East Industrial Context

The Gulf industrial sector is changing very fast. Specifically, metal engineering Oman now utilizes high grade polymers more than ever. Similarly, there is a huge demand for materials that can survive harsh weather conditions.

Furthermore, many metal manufacturing companies in UAE are now diversifying their product lines. They provide engineering plastics alongside their traditional steel and metal supply. Because of this, these plastics perform exceptionally well in the extreme heat of the region. In contrast to some metals, they do not suffer from thermal stress.

Role of Engineering Plastics Manufacturers in Modern Industry

Many businesses in Saudi Arabia rely on specialized suppliers for their structural steel needs. For internal gears and precision parts, engineering plastics often provide a superior alternative. These polymers are much lighter and more cost effective than traditional metal manufacturing.

Industrial leaders across the UAE and the GCC now adopt hybrid models. These firms combine the strength of metals with the efficiency of plastics. This approach represents a new industry standard for excellence. By integrating both materials, businesses achieve better durability and cost efficiency in their industrial projects in Oman and the wider region.

Sourcing Engineering Plastics in UAE, Saudi Arabia, and Oman

Finding the right supplier is the most important step for cost efficiency. Currently, you can easily find stainless steel suppliers in UAE or Saudi Arabia. But in addition to metals, you must also consider high performance polymers.

Overall, the supply chain in the Middle East has become very mature. For instance, many metal trading companies in UAE now supply both metals and plastics. They provide iron bars for construction and, similarly, offer plastics for high precision engineering.

Conclusion: The Strategic Shift

The debate is not just about carbon steel vs stainless steel. It is about choosing the best material for the job. Engineering Plastics provide better performance and cost savings.

The metal industries in UAE continue to innovate. The mix of ferrous and non ferrous metals with advanced plastics is the future. This synergy will drive the next industrial revolution.