Comparing PTFE vs Nylon vs Acetal is essential for engineers across the UAE and Saudi Arabia. These three engineering plastics offer unique properties for different industrial applications. In the GCC, selecting the right polymer determines the durability of machinery parts. Whether your project is in Oman or the UAE, understanding these materials ensures better performance and cost efficiency.

Comparing PTFE vs Nylon vs Acetal Properties

To make the right choice, you need to examine how each material handles heat, friction, and environmental stress.

PTFE (Teflon) stands out for its chemical resistance and ability to withstand high temperatures. It stays soft and maintains a very low coefficient of friction.

Nylon (Polyamide) serves as a tough, wear resistant material. It handles high loads and impact better than most plastics but tends to absorb moisture over time.

Acetal (POM) features impressive stiffness and dimensional stability. Unlike Nylon, it rejects moisture, which makes it ideal for precision parts that must stay the same size in wet environments.

Performance Analysis of PTFE vs Nylon vs Acetal

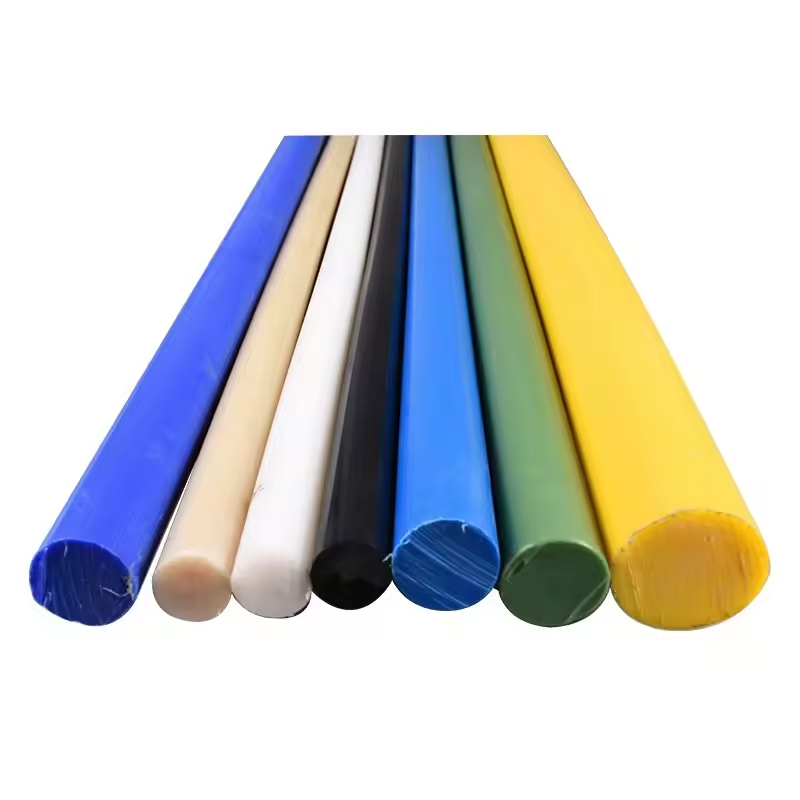

When you source materials from a metal trading company in UAE that also specializes in plastics, you will typically find these materials in sheets and round bars. Here is where each one excels in the Middle East industrial market:

1. PTFE (Polytetrafluoroethylene)

PTFE is famous for its extreme chemical resistance and high temperature stability. In the metal industries in UAE, it is often used for seals and gaskets that face harsh chemicals. It has the lowest friction of any solid material. This makes it ideal for specialized industrial projects in Saudi Arabia where heat resistance is a priority.

2. Nylon (Polyamide)

Nylon is the go to material for high load applications in the GCC region. It offers excellent wear resistance and great mechanical strength. Many metal manufacturing companies in UAE use Nylon for gears and bearings. It absorbs some moisture, so it is best used in environments where dimensions can vary slightly. Its toughness is highly valued in the industrial sectors of Oman.

3. Acetal (POM – Polyoxymethylene)

Acetal provides high stiffness and excellent dimensional stability. Unlike Nylon, it does not absorb much moisture. This makes it perfect for precision parts that must keep their exact shape. Industrial suppliers in Saudi Arabia recommend Acetal for fuel system components and small gears. It is a reliable choice for high performance engineering in the UAE.

When to Replace Metal with Plastic?

Many industries in the GCC switch to these engineering plastics to reduce maintenance costs. Plastic parts weigh less, resist rust, and often run quieter than their metal counterparts.

However, for structural support where extreme tensile strength remains necessary, traditional metal products or corrosion resistant alloys act as the safer option. A reliable supplier can help you analyze your project requirements to see if a switch is feasible.

Final Verdict on PTFE vs Nylon vs Acetal

Selecting the winner depends entirely on your environment. Do you need heat resistance (PTFE), wear resistance (Nylon), or precision in wet conditions (Acetal)?

By consulting with a specialized supplier who understands both metals and plastic manufacturers, you ensure access to the exact grade needed for your machinery. Partner with us today to explore our range of high performance engineering plastics and find the perfect fit for your next project.