Technical Specifications

Properties & Notes

- Carbon content typically ranges from 2.0‑4.5% and silicon from 1.0‑3.0%, which governs graphite formation and mechanical behaviour.

- Exceptionally good compressive strength, but relatively low tensile strength and ductility compared to steels.

- Excellent machinability and vibration damping (especially grey cast iron) due to graphite flake structure.

- Wear‑resistant and stable in static heavy load conditions; brittle behaviour under shock or impact must be considered.

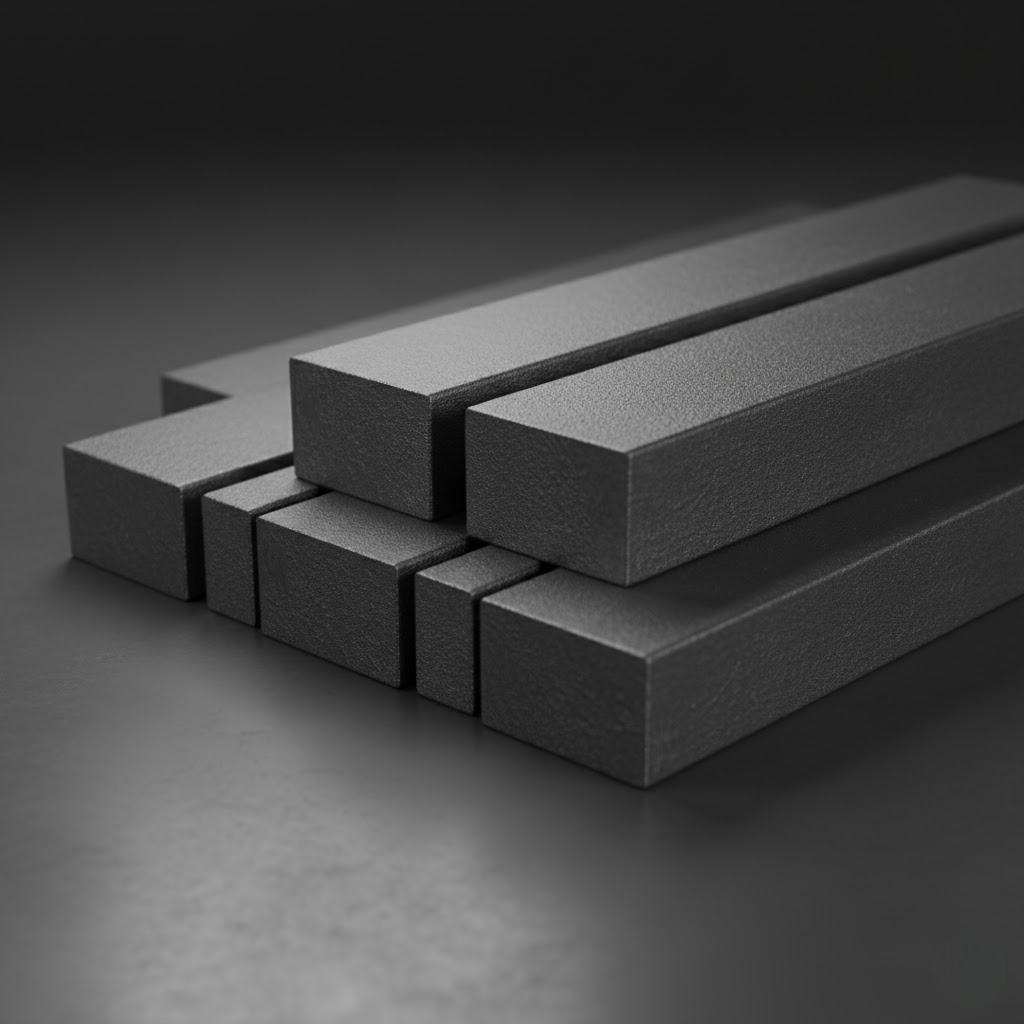

- Wide variety of types (grey, white, ductile/nodular, malleable, CGI) each with unique balance of strength, ductility and wear resistance.

When selecting cast iron for projects, choose the appropriate type (e.g., ductile for higher toughness, white for wear resistance) and design for compressive loads or static conditions where its advantages can be maximised.

Additional Notes

- Graphite morphology (flake vs nodular) significantly influences properties: ductile iron offers improved ductility and impact resistance vs grey cast iron.

- Casting parameters (cooling rate, alloying additions) are critical in achieving desired microstructure and properties.

- Surface finishing, machining allowances and heat treatments need careful consideration to mitigate brittleness and enhance performance.

- Often used where cost, cast complexity and static performance matter more than dynamic loading or high tensile demands.

For heavy‑duty industrial castings, specifying the correct type of cast iron and controlling casting and heat‑treatment processes are essential to get the performance required in your application.