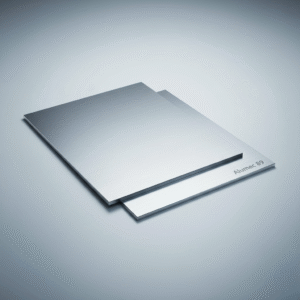

5083 aluminum H114 is a widely used marine grade material known for its strength, corrosion resistance, and reliability in demanding environments. Moreover, aluminium alloy 5083 performs exceptionally well in applications exposed to moisture, chemicals, and fluctuating temperatures, making it a preferred choice for long-term industrial and structural use. In addition, it provides consistent mechanical properties, even under extreme conditions, which ensures durability over time.

AA 5083 offers excellent weldability and also maintains stable mechanical properties after fabrication. As a result, this high strength aluminium alloy supports lightweight construction without compromising durability. Therefore, it is suitable for transport, offshore, and heavy duty engineering projects across the UAE, Oman, and Saudi Arabia. Furthermore, its resistance to harsh conditions makes it ideal for both marine and industrial applications.

Key Benefits of 5083 H114 Aluminum

- Excellent resistance to seawater and harsh industrial conditions

- High strength to weight ratio for structural applications

- Good fatigue performance and weldability

- Suitable for marine, cryogenic, and pressure vessel use

- Supplied by experienced 5083 aluminum suppliers and aluminium manufacturers in UAE

- Tensile Strength: 275–350 MPa

- Yield Strength: 125–200 MPa

- Elongation: 10–17%

- Modulus of Elasticity: 70 GPa

- Hardness: Approx. 80 HB

With widespread availability across the UAE and GCC, 5083 H114 is a top choice for companies seeking a high strength aluminium alloy that balances performance, durability, and reliability. Whether for shipbuilding, offshore structures, cryogenic tanks, or heavy duty industrial components, this alloy delivers exceptional results and long-term value.