Alumec 89 is a high strength aluminium alloy designed for tooling and prototype applications. Its excellent machinability, low weight, and high thermal conductivity make it ideal for moulds, tooling components, and engineering parts requiring precision and dimensional stability. Aluminium sheets, aluminum plate, and aluminium bars from this alloy support fast fabrication and consistent performance.

Industrial metal suppliers and aluminium manufacturers in UAE, along with metal engineering Oman, provide Alumec 89 for tooling, short-run production, and prototype applications. Its good corrosion resistance and stability make it suitable for surface treatments such as hard anodizing, nickel, or chrome plating.

Key Benefits of Alumec 89

- High strength aluminium with excellent machinability

- Lightweight alloy for easier tool handling

- High thermal conductivity to reduce cycle times

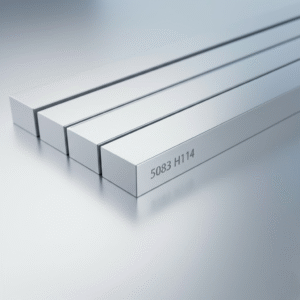

- Available as aluminium sheets, aluminum plate, and aluminium bars

- Ideal for tooling, moulds, prototypes, and precision engineering components