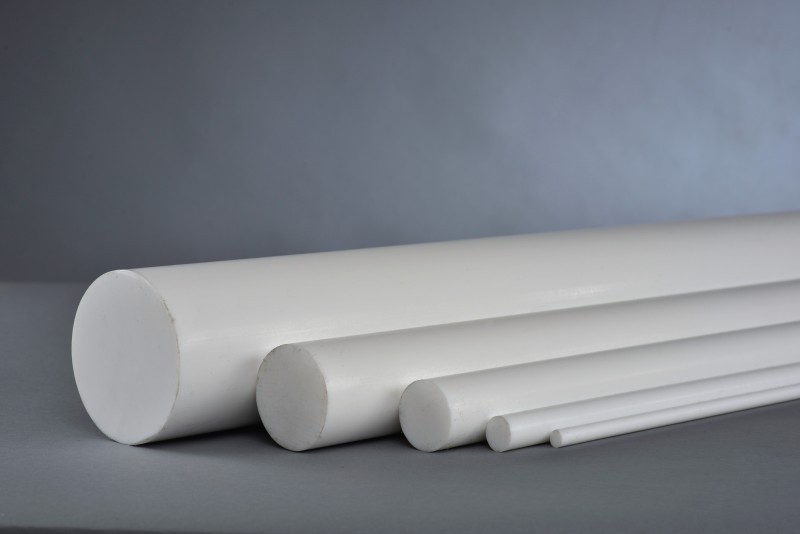

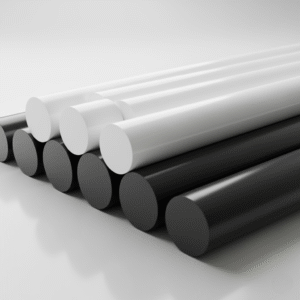

PTFE Teflon is a high performance fluoropolymer valued for its chemical stability, low friction, and reliable operation in extreme conditions. Also known as polytetrafluoroethylene teflon, this teflon material suits applications where resistance to chemicals, heat, and wear is critical across industrial and technical environments.

It also delivers consistent results in processing, sealing, and insulation applications. PTFE Teflon keeps components stable across a wide temperature range while maintaining surface purity. For this reason, it is ideal for chemical handling, food processing, electrical systems, and precision manufacturing.

Key Advantages of PTFE Teflon

- Excellent resistance to aggressive chemicals and solvents

- Very low coefficient of friction for smooth operation

- Reliable performance at both high and low temperatures

- Strong electrical insulation and non stick surface properties

- Low moisture absorption and high purity surface behavior

Additionally, industrial users rely on teflon material supplied by plastic manufacturers and plastic raw material suppliers for high performance applications. Metal trading companies in UAE actively support fabrication, helping engineers and manufacturers produce precise, long lasting components in demanding environments.